by Richard H. Johnson

in Soaring Magazine 9/2003

A report on a new and versatile high-performance two-seater.

INTRODUCTION

The DG-1000S is a new 18/20-meter two-seat high-performance sailplane that recently entered production at DG Flugzeugbau in Germany. It is really an impressively beautiful and well-engineered sailplane, and a joy to fly. I am sure that Wilhelm Dirks, DG’s legendary sailplane designer and engineer, had a large hand in its design. When John Earlywine offered to bring his new DG-1000S sailplane from Ft. Wayne, Indiana to Texas for winter flight testing, we were excited with the prospect.

John and experienced crewman Lach Ohman arrived at Caddo Mills on the last day of February. We assembled the glider and started taking photographs, and making measurements. We decided to do most of our testing with the 20-meter tips installed, but we did reserve a couple of test flights for 18-meter handling and spin testing.

The DG-1000S is available with 3 different versions of the undercarriage:

A. A very high sprung, retractable main wheel with disc brake and tail wheel (for highest performance).

B. A high sprung, retractable main wheel with disc brake, tail wheel, and nose wheel (like the Duo Discus).

C. Fixed sprung main wheel with drum brake, tall wheel and nose wheel (mainly for club type use).

The main undercarriages for versions B and C are interchangeable. Our flight test sailplane had the high-performance A configuration.

The workmanship and detail design of our test sailplane were outstandingly good. Its gel-coated exterior surfaces were beautifully smoothed, polished, and waxed. Both of the canopies fit exceedingly well, and the cockpits were relatively quiet during flight. The wing surface waviness was very low, averaging well below the .004″ limit that I believe necessary to achieve extensive low drag laminar flow on sailplane wings.

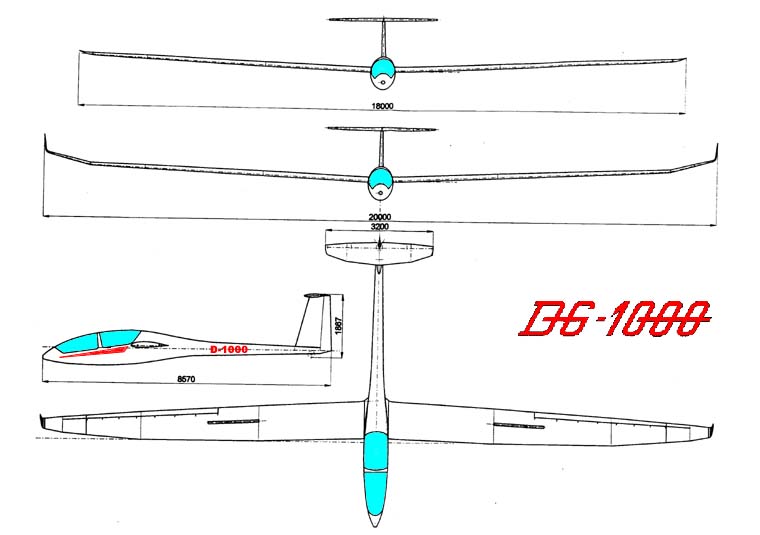

The 20-meter wing area is about 188.6 square feet, and its aspect ratio measures about 22.8. Its airfoil is reported to be a new laminar section designed by Professors Horstmann and Quast from DLR Braunschweig, and designated HQ-51. This section was reviewed and measured at Stuttgart University. The Technical University of Delft then completed the design with the addition of winglets and optimized the wing-fuselage intersection with the assistance of Loek Boermans, the well-known aerodynamicist. The wing has no flaps, and the airfoil appears to be well optimized for mid-speed performances.

The carbon- and glass-fiber epoxy composite construction appeared to be quite strong. All exposed metal fittings were nicely cadmium plated for enduring rust protection. Its retractable main wheel is a generously-sized 15 by 6-inch (380 by 150 mm) Cleveland unit equipped with a powerful hydraulic disk brake, which functioned so well that one needed to be careful not to pitch the sailplane’s nose down into the runway. The aft end of the fuselage is equipped with a standard Tost 200×50 mm pneumatic tail wheel. A nose tow hook was installed in our test sailplane that made aero towing very easy. The nose tow hook is standard equipment, and it is mounted in the center of a relatively large nose air inlet. A second CC tow hook (also standard) is mounted well aft of the fuselage nose, on its bottom side for winch and ground tow launching.

AIRSPEED CALIBRATION

The DG-1000S airspeed system uses a pitot mounted flush with the fuselage nose. Two orifices close to the fuselage nose provide the static source. First we checked the pitot and static system lines for leaks, and found none. Then, inside the hangar and out of the wind, we calibrated the sailplane’s Winter airspeed indicator by carefully comparing its readings to our calibrated reference ASI meter. The errors were very low – less than about one knot over our entire planned flight test range!

We performed our airspeed system flight calibration following a 9,000′ tow in smooth air, with a Kiel tube pitot reference temporarily taped to and extending 6″ from one side of the canopy. After tow release a trailing bomb static reference was deployed about 50 feet below the sailplane, suspended by 7-mm vinyl tubing. The flight test calibration was performed by steadily flying at indicated airspeeds of 42.5 to 120 kts, comparing our master reference indicated airspeeds to those of the sailplane. Those test data were then used to compute the DG-1000’s airspeed system errors versus indicated airspeed. These errors appear to be generally about linear with airspeed, varying from + 1. 5 kts at 40 kts, to about -2.5 kts at 120 kts. They show that the sailplane is actually flying about 1.5 kts faster than indicated near stall, and about 2.5 kts slower than indicated at 120 kts IAS.

Because the airspeed pitot is close to the nose tow hook, it is likely that when a tennis ball or other large tow ring protector is on the end of the towrope, the airspeed pitot will receive less than its normal impact pressure, causing a low airspeed indication while on tow. It has been my experience that tow ring protectors are often used in the U.S. when operating from hard-surface runways. I do not recall them in Europe, where most operations are from grass runways.

While the fuselage nose side orifices provide a very satisfactory reference static pressure source, they are subject to clogging when flying through rain. For that reason a pneumatic switch of some kind should be installed, teed into the sailplane’s static pressure line, so the pilot can switch to an alternate static source if and when clogging. The cockpit usually provides a fairly good static reference pressure, and I have used that many times in the past.

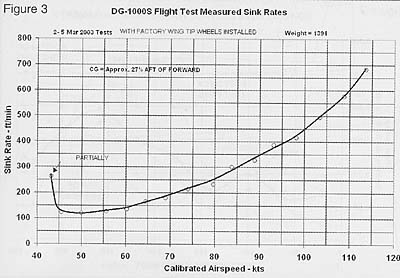

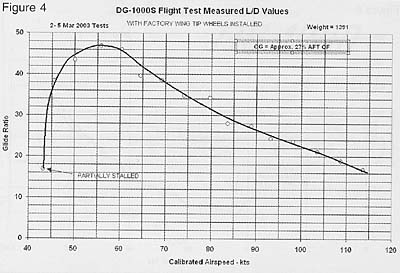

SINK RATE TEST FLIGHTS

Five high test flights were performed to measure the DG-1000S ‘s sink rates at indicated airspeeds from 42.5 to 115 kts. John piloted those flights from the front cockpit, while I recorded the data in the rear cockpit. We really should have changed cockpits for those tests because John is much larger than I am, and the sailplane’s CG would have been in a more favorable location (62% versus 25% aft of forward limit).

These tests were performed with small factory-supplied wheels installed at the wing tip trailing edges. These were encased within well-streamlined molded fairings that allowed only the bottom most portion of the small 60-mm diameter wheels to be exposed to the air stream. They added a small amount of drag to the sailplane, but likely not very much. The tip wheels and fairing’s are now standard equipment. However, they can be replaced with optional small bolt-on aluminum racing skids.

WING OIL FLOW TESTS

The factory had installed full-span dimpled turbulator tape on the wing bottom surfaces at the .75 chord location. A single wing oil-flow test flight was performed at about 50 lets airspeed, mostly while circling in weak thermals. A plot of the oil flow pattern data is shown in Figure 5. The resulting oil flow patterns all appeared to be normal at that relatively slow minimum sink airspeed. The wing bottom-surface oil flow patterns indicated extensive low drag laminar flow to about the 70- to 75-percent chord location, and no high-drag airflow separation bubbles were observed anywhere along the span. These data indicate that the factory installation of the turbulator tape at the .75 chord location was unnecessary, at least at our 50-kt test airspeed.

The corresponding wing top-surface oil flow patterns indicated low-drag laminar flow to only about the 35- to 42-percent chord locations. That is probably about normal for a limited-camber relatively high-speed airfoil, operating at our relatively high angle-of-attack 50 kts test airspeed flight condition. At higher airspeeds the wing top surface’s laminar airflows would likely have extended much farther aft. There was no turbulator tape installed on the wing top surfaces, and no high-drag airflow separation bubbles were observed from the oil flow patterns anywhere along the span.

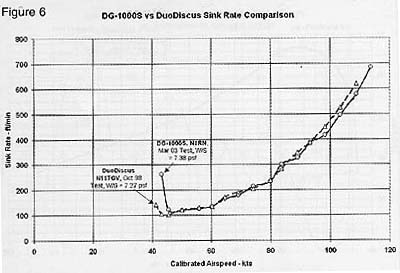

PERFORMANCE COMPARISON

The empty weight of our fully equipped 20-meter DG-1000S was actually about 17 lbs less than our previously tested DuoDiscus, according to the factory documents: 908 lb vs. 925 lb. However, because of the heavier cockpit loadings, our DG-1000S performance flight test weight ended up being about 102 Ibs heavier. The high cockpit loading required that the full complement of 6 factory-supplied tail weights (26.5 lb total) be installed. Despite this, the CG location was still only about 27% aft of its forward limit.

WING SURFACE WAVINESS MEASUREMENTS

We made chord wise waviness measurements of the DG-1000S’S wing top and bottom surfaces at nine span wise stations along each wing, using a standard 2-inch long wave gage. The wing surface waves were quite small, averaging only a little more than .002″ peak-to-peak, and that is excellent. Only at two places near the wingtips did our measurements slightly exceed my .004″ maximum recommended value for low-drag laminar airflows. These waviness measurements are for peak-to-peak magnitudes from valleys to peaks.

GENERAL CHARACTERISTICS

Commendably, all of the DG-1000S’s controls connect automatically upon assembly. The wing root spars have the excellent fork-and-tongue arrangement that I think is superior to the commonly used overlapping single spar roots. The left wing spar root is the forked one, and it is inserted first during assembly, completely filling the square fuselage mounting slot. The single-tongued right wing spar root is then easily inserted into the left wing’s forked spar. The left wing is thus a bit heavier: it weighed about 198 lbs, 2 pounds more than the right wing.

The two roomy cockpits are enclosed by excellent side-hinged canopies, and the Plexiglas canopy itself had very good optics. The DG-1000S is easy to fly, handles well, and the cockpits are comfortable and well configured. Its stall characteristics are gentle, with almost no tendency for the sailplane to drop a wing during my low-airspeed maneuvering tests. My 45-to-45 degree roll rate measurement tests showed about 6.5 seconds at 51 kts indicated.

The double-plated wing top-surface-only airbrakes are quite adequate, providing good glide path control during landings. Water ballast tanks are installed in each wing leading edge, capable of holding a total of about 160 liters, or about 353 pounds. A small tail fin water ballast tank is included, and it holds about 6.2 liters, or about 13.7 lbs. There are 3 dump levers: a wide lever for the tail tank covers the 2 wing tank levers, so the tail tank must be dumped to empty the wing tanks.

The thermals during our late-winter Caddo Mills flight testing were weak, so I was able to soar the DG-1000S from the front seat for less than an hour. Lach Ohman was my passenger. Our CG for those flights was at about 75% aft of the forward limit. During that limited testing, I thought that it thermaled fairly well. Dean Carswell performed the sailplane’s flying qualities testing a few days later. He was able to better evaluate the DG’s thermalling flight characteristics. I accompanied Dean on one of his evaluation flights where he performed thermalling, stall, and spin testing. The sailplane’s CG at about 78% during that flight, and the sailplane performed well. His evaluations accompany this article.

The current price of the new 20-meter DG-1000S with winglets is 76,040 euros, plus trailer and shipping. Instruments and optional auxiliary items, except for an outside air temperature gage, are not included in the sailplane’s basic price. The 18meter fixed-gear version is priced at 65,490 euros. For more information go to: www.soarfl.com, or to the factories excellent website at www.dg-aviation.de.

SUMMARY

The new DG-1000S sailplane is, in my opinion, an excellent sailplane for pilots who want a fine high-performance two-seat sailplane. It appears to be of high quality in design, construction, and finish. Its powerful Schempp-Hirth type airbrakes are easy to operate and provide very good landing approach control.

Many thanks go to John Earlywine and Lach Ohman, my excellent olden-days crewman, for bringing this fine new sailplane all the way to Texas and assisting with its flight testing. Also to the Dallas Gliding Association for providing both the hangarage and the necessary high aero tows, and to Southwest Soaring’s manager Mike Salano and his Caddo Mills staff and tow pilots who did the excellent towing.

REFERENCES

A. Richard H. Johnson and Dean Carswell: A Flight Test Evaluation of the Duo Discus Sailplane, Soaring, March 1999.

B. Dean Carswell: Sailplane Type Conversions, Soaring, September 1996.

About the author: Dick Johnson is well-known in the soaring community, and has graciously provided the readers of Soaring Magazine with flight test evaluations of sailplanes through the years.

AN INSTRUCTOR’S THOUGHTS ON FLYING THE

DG-1000S

by Dean Carswell

The DG-1000S is the exciting newcomer to DG’s stable of two-place sailplanes. Initial evaluation shows it to be a well harmonized, comfortable sailplane with very good cross-country potential. DG’s rationale for developing it reportedly began with an assessment of the Schleicher ASK-21, regarded by DG as the ideal glider for flight training, the Schempp-Hirth DuoDiscus as the most modern 2-place designed especially for cross-country flying, and its own 18/20m DG-505 Orion with good training capabilities, cross-country performance and aerobatic ability. DG considered that it could design and build a sailplane combining the best of all three is; the result is the DG-1000S. At the moment, it is offered only as a pure sailplane, but the DG-1000T with a 30-hp Wezel single-cylinder two-cycle sustainer engine is planned for 2004.

The 1000 is offered with an unflapped 17.2m span trapezoidal (think Discus-shaped) wing and a choice of tips giving 18m span for training and aerobatics, and 20m with winglets for best cross-country performance. It has been designed to conform to JAR 22 standards, and has an FAA Approved Type Certificate. Limited aerobatics are permitted with the 18m tips, with additional maneuvers allowed if the gross weight does not exceed 1,389 lb (‘g’ limits increase to +7/-5). The test sailplane, s/n 10, came with both span options and the long-stroke retractable sprung main gear (without nose wheel) located slightly ahead of the loaded CG. This adds to the initial impression of the 1000 as a large – the cockpits stand high off the ground, and graceful entry requires a tall pilot, fitness, or a footstool.

The tandem cockpits, with separate side-opening canopies, are roomy with very deep seat pans – a good safety feature. Entering the front seat requires a little care to prevent long pants becoming tangled with glider parts. A 6′ 2″, 265-lb pilot declared both cockpits to be comfortable. The rear cockpit is raised slightly above the level of the front to improve forward visibility for the rear pilot. The controls come easily to hand with airbrake and landing gear levers both situated against the left cockpit wall and duplicated in the rear cockpit. The airbrakes come equipped with a “Piggott Hook” which limits lever travel to a couple of inches if the airbrakes are inadvertently left unlocked – another good safety feature.

The elevator has a bias spring trim operated by a small trigger on the front of each control column. There are also trim quadrants on the left cockpit wall which give a visual indication of the trim setting. The front-seat rudder pedals are ground- and flight-adjustable; both the pedals and the seat back in the rear are fixed. The rear seat has an unusual feature: the seat pan pivots at its front edge, allowing for height adjustment with a webbing strap. This lets the eyeline of the rear pilot be raised to improve forward vision – the limiting factor is the need to maintain adequate headroom beneath the canopy. The lack of pedal/seatback adjustment did not seem to cause any problem for occupants with heights varying between 5′ 7″ and 6′ 2″.

Permitted cockpit weight is governed by JAR 22; the minimum front seat weight for solo flight is 148 lb. Water ballast up to 42.3 U.S. gallons (353 Ibs) can be carried in the wings to raise wing loading and permit optimum performance to be achieved at higher airspeed. There is a 1.6-gal tank in the tail to provide trim compensation when the wing ballast tanks are used.

The 1000 also has an unusual solid ballast system, consisting of 6 brass weights totaling 26,5 lb that can be placed in a compartment in the vertical fin to adjust the glider’s center of gravity – primarily to reduce tail plane trim drag, but also to enable spins to be demonstrated. I really liked this feature as it allows realistic spin training – lack of this ability in many 2-place sailplanes risks an important gap in a student’s training. The ballast compartment has a transparent cover to simplify visual checking. The same weights can be used in the cockpit should it be necessary to compensate for a lightweight front seat occupant. Needless to say, with the possible permutations and combinations of ballast, care needs to be taken to ensure the glider is operated within permitted CG limits. An electronic indicator in the front instrument panel helps by showing the number of fin weights installed. All of this should be a clear warning to apply with care a “CB SIFT BEC or other pre-takeoff checklist to ensure safe loading.

Empty weight of the test was 907 lb (11.5 lb less with the 18m tips); certified max. gross is 1,653 lb. The 20m tips give a wing area of 188.7 sqft and a maximum wing loading of 8.76 lb/sqft. Redline speed in both configurations is 146 kts and a yellow-triangle speed (recommended lowest approach speed at maximum weight without water ballast) is 54 kts. The maximum demonstrated crosswind component is 8 kts, but this is likely a low estimate of actual safe capability.

I made three flights in the – two in the front seat with rear seat occupants weighing up to 265 lb and one in the rear seat when the front seat occupant weighed about 150 lb, a weight similar to mine. Two flights were made with the 20m. tips and the third at 18m span. Trim weights were added to the fin to put the CG close to the aft limit so any adverse handling qualities would likely be more apparent.

Weather was 35′ F with broken clouds and a surface wind of 10-15 kts, more or less down the runway. Even so, there was a little weak scrappy thermal lift. Wing dihedral gives good tip clearance – a good safety feature, particularly in a glider used for training. The aero tow hook is fitted at the extreme front of the long nose. This appeared to have a good directional stabilizing effect while the DG-1000 accelerated on the take-off roll. As expected on a glider of this size, control sensitivity is moderate, with very little risk of over-controlling. The ailerons are responsive from very low speed, but feel a little heavy. Once airborne, the view ahead is excellent, even from the rear seat, where the ability to raise the pilot’s eyelevel is clearly a benefit. In general, the controls felt responsive on tow, although the relatively smooth conditions did not provide any real challenges.

Off tow, control harmonization was good. Raising the gear, which can be accomplished from either seat, felt a little heavy, but the gear lever is well positioned to give the pilot good leverage. Pilots would be well advised to delay raising the gear until after release from tow to avoid a potential risk while retracting the gear. With the 20m tips, adverse yaw is considerable, but at the yellow-triangle speed the large rudder can balance a roll with full aileron applied; slowing down to 48 kts there is not quite enough rudder authority to be fully coordinated. The spring trim is easy to use and effective – it can eliminate elevator forces all the way up to the bottom of the yellow arc (100 kts). Visibility, from either cockpit, is nothing short of remarkable – it is possible to see through almost the whole 360 degrees, only a few inches of the horizontal tail plane next to the fin is not visible. Ventilation is very good, both from the scoops on the canopy, and through a well-placed eyeball louvre set on the right side of each cockpit. The very low level of cockpit noise is worthy of comment: it’s achieved without a rubber gasket or other seal between canopy and frame, simply by very accurately profiled GRP surfaces mating together.

As I have already implied, handling is pleasant, and the 1000 sat steadily in the weak narrow thermals at 30 to 40 degrees of bank with little need for control inputs. While the conditions were more a test of the pilot than the glider, it thermals easily and comfortably, and should not be a big challenge even for a low-time pilot. Exploring the low-speed handling showed just a slight tail plane buffet a couple of knots above the stall – only a subtle warning, which might be missed by a distracted or inexperienced pilot. With the 20m tips, this occurred around 37 kts with a 320-lb cockpit load and about 3 kts higher with a 435-lb load. Airbrakes open raised the stall speed by 2-3 kts.

In each stall except a turning stall to the right, the glider dropped the left wing; recovery is swift as soon as the back pressure on the stick is relaxed. At close to aft CG, in 18m, configuration, there was little difficulty inducing a spin from a cross-controlled skidding turn, although substantial control deflections are needed. A little surprisingly, the nose nodded upward during the departure, but following the standard drill resulted in immediate recovery, with some height loss and the airspeed peaking around 80 kts.

As some surplus height remained after spinning, I attempted a loop and a stall turn which were easily and enjoyably accomplished. I was surprised at the fast rate of acceleration as the glider was dived down to get entry speed – a good sign for a sailplane designed, in part, for aerobatic training, when the pilot wants to minimize height loss while trading height for speed to get started. The double-segment top-surface Schempp-Hirth type airbrakes are effective, and operation results in little pitch change. The Piggott-Hook is bypassed by rotating the airbrake lever inboard during the first few inches of travel. If ever required, the 1000 can be slipped to materially increase the descent rate. In the process, rudder overbalance occurs at close to full deflection, meaning a firm push on the pedals is required when discontinuing the slip. Approach control is easy, again with excellent forward view of the field and runway. Touchdown is nicely cushioned by the sprung main gear. On rollout, directional control is good and, in the prevailing conditions, the ailerons remained effective until the glider had slowed to walking speed.

The Cleveland hydraulic disc brake, operated by the airbrake lever, is powerful and, carelessly applied, could easily result in the nose being pitched down with possible minor damage to the finish of the glider.

Conversion issues should be minimal with a qualified instructor or experienced DG-1000S pilot to accompany the pilot being checked out. As always, a careful and systematic approach to conversion will pay dividends and avoid surprises.

In conclusion, the DG~1000S is a delightful state-of-the-art two-place sailplane that can be used as a serious cross-country as well as a general-purpose and acrobatic trainer. It is an excellent platform for cross-country instruction. Its main wheel/tail wheel configuration and retractable gear should make it a good glider for converting low-time pilots to high-performance flapless gliders even if pitch and roll sensitivity is quite different from the typical 15m single-place sailplane.

While I hesitate to make comparisons between different make/models, especially when not compared side by side, DG seems to have designed a cross-country very comparable to the DuoDiscus while adding the possibility of training and aerobatics. I am bound to say that its size and cost probably make it less attractive as a general-purpose trainer – I would have just a few qualms sending a student on first solo in a glider which costs around $95,000, although logically there is nothing intrinsically wrong with doing so.

About the author:

Dean Carswell holds a Gold badge with two Diamonds, has been an active gliding instructor for over 35 years, and is presently the SSKs Chief Master Instructor. He normally flies from Texas Soaring Association’s glider port at Midlothian, TX, where he is the chief flight instructor.