The following article was published in the German “Fliegermagazin”.

It is with many thanks to the Author Jochen Ewald for allowing us to publicize his article.

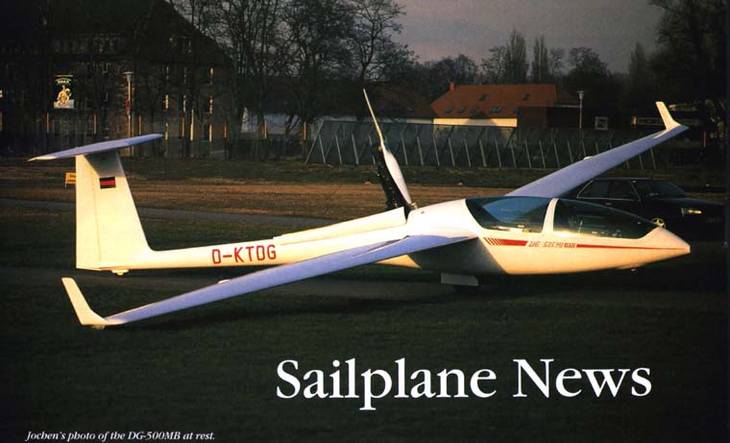

DG-500 and DG-500M are well known as a high performance double seater motor gliders.

Since 1987 Glaser-Dirks have been producing the 22 Meter wingspan glider and motor glider in Bruchsal. The chief constructor Wilhelm Dirks is now introducing the newest version of the successful retractable two-seater.

Jochen Ewald had the opportunity to test fly the ship.

It all began with one meter: The Karlsruher Akaflieg decided to fit their DG-500 to the new 20-Meter competition class for two-seater gliders.

The students shortened each wing by one meter. In order not to lose to much flight performance, the students added winglets to their shortened wings.

The manufacturer estimated the resulting glider and it’s flight performance well.

The new wing was optimized for production and is now being offered in two different wingspans, thanks to the four part exchangeable wing pieces in 20 or 22 meters.

The Wortmann FX-73 wing profile of the DG-500 Series (produced since 1987)

is still being used today.

In the new DG505, and the motorized DG-505MB version, customers wishes were taken into account.

In the new DG505, and the motorized DG-505MB version, customers wishes were taken into account.

Improved are the leg supports in the front cockpit, this allows larger pilots more room. In the rear cockpit, the instrument holder was formed to prevent the pilot from squeezing his thumb between the control stick and instrument panel.

For an engine, DG selected a power machine. The original Rotax engines are no longer being produced, so DG was forced to look for a new supplier. They settled on a water cooled Solo 2625. In the DG-505MB they are using the most powerful version of the new standard engine being used today in the German retractable engine scene!

With two carburetors, the Solo 2625-2 now has 47 KW / 64 HPS starting power.

The mounting of the 20 Meter four part wings is no problem for two people and the proper tools. A mounting carriage allows for a comfortable folding and installation of the heavy inside wing. All steering elements automatically connect when the wing is pushed into place. The two main pins are secured with a screw. These are not to be forgotten, they stop the spars from bending apart under pressure!!

The rear securing bolts are pushed through the top of the wing and are then automatically secured by a spring snapper, once the mounting handle is removed!

The outer wings with winglets are pushed into place, and with a built-in bolt fastened and secured.

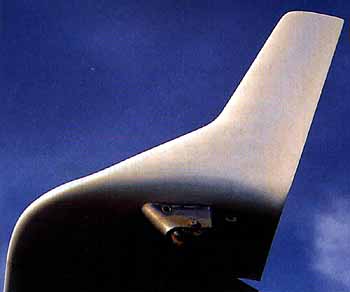

The elevator unit with automatic Ruder connection is mounted on top. It is properly secured when the head of the bolt disappears into the contour of the tail fin.

The prototype is with 585 kilograms empty weight, still relatively heavy. The DG-505MB was developed by changing the DG-500B prototype.

The production series will be approximately 15 kilograms less. The maximum starting weight is 825 kilograms.

The motor glider will come with a 38 liter fuselage tank. The tank can be filled with 2-stroke fuel using the filling system, or directly in a filling connection built into the fuselage.

There are two 15 liter wing tanks which can also be purchased as an option, as well as two 50 liter water ballast bags. The water ballast bags allow lighter pilots the maximum wing loading of 47 kilograms per square meter.

When sitting in the cockpit, one becomes a certain “Mercedes-Feeling”.

When sitting in the cockpit, one becomes a certain “Mercedes-Feeling”.

There is a lot of room for both pilots, a comfortable interior, good seat positioning and an excellent view. All of the things that DG pilots have come to expect.

Flight trainers especially like the capability to adjust the rear seats height and angle.

The system with the harness attached to the back of the rear seat pan looks primitive, but it has proven to be effective over the years.

Let us look around the Cockpit:

The handle on the left side of the canopy frame which is used to secure the canopy latches, as well as the emergency eject handle on the right side have both been positioned further forward. This allows for better access.

Important for the safe use of the motor gliders in training is the DEI (Digital Engine Interface) – developed by DG – which is installed in both panels. This allows the control of the engine from both seats. The DEI connects motor steering functions and the warning instruments in one unit.

Brake flaps, landing gear and flap handles, as well as the trimming control knob are all situated on the left hand side as has become a custom of DG gliders.

The brake flap handle is attached to the hydraulic disk brake of the main wheel.

On the control stick you will find the trimming release handle. The rudder pedals are connected with the nose wheel, which can be steered.

On the right side of the glider interior it is still quite tight. Because the DG-505B prototype was changed to a motor glider after it’s original construction the fuel cock, water and wing tank handles are still not located in their final positions in the cockpit.

Also located on the right side is the emergency engine retract knob. Should the electrical system malfunction, the propeller can be stopped with a mechanical brake and retracted using the emergency knob.

Very practical and nicely situated are the security switches for the power supply on the lower half of the instrument board.

Should the battery be empty after a longer flight pause one can recharge the battery using a starter cable attached to a car battery.

When you climb into the glider it dips toward the nose wheel. Main switch and ignition in the “On” position, and you will see the propeller within some seconds in the mirror, which is located on top of the instrument board. One push of the ignition button and the powerful engine comes to life.

When you climb into the glider it dips toward the nose wheel. Main switch and ignition in the “On” position, and you will see the propeller within some seconds in the mirror, which is located on top of the instrument board. One push of the ignition button and the powerful engine comes to life.

The fuel injection during the start is controlled by the DEI. The advantage of a powerful engine becomes evident when rolling on a soggy ground to the asphalt starting point. In most cases one would sink into the soft ground.

Thanks to the small wing tip wheels, it is possible to roll independently.

The steer able nose wheel allows, to turn around on a wingspan. If the weight in the cockpit is close to the rear position of the center of gravity then the nose wheel has less loading pressure.

The DG-505 tends not to react to the vertical stabilizer if there is not enough pressure on the nose wheel. In this case you must give a little more power and extract the brake flaps which activates the wheel brake. Now you will be able to steer the glider in the desired direction.

Before getting started, I do a magnet check of the double ignition system and set the flaps to the starting position of plus ten degrees. After a few meter I am able to lift the wings into the horizontal position. Wind gusts from either side are hardly noticeable.

The DG speeds up rapidly, while maintaining a steady course. By 75 Km/h you can takeoff !!

Before I concentrate on the climbing flight, I retract the landing gear and reduce the RpM to the maximum maintainable level of 6300 RPM. With a perfect climbing speed of 95 Km/h the DG climbs single seated to 1000 meter in five and a half minutes. Two seated the DG climbs to 1000 Meter in six and a half minutes!

The view from the cockpit is incredible. The typical DG canopy which extends forward quite low offers an active safety feature, especially when the airspace is crowded.

Both pilots have the handle and adjustable air vents on the right side of the cockpit.

The noise level in the cockpit is acceptable, however the use of the headset which is included in delivery is recommended.

The outer noise level is positively speaking, very quiet as are all of the new motor gliders with engines that retract into the fuselage!! The installation of the engine has been solved very well.

Reducing the power sinks the trim setting by only 10 Km/h. The traveling speed in power flight is with 150 Km/h and 6200 RpM very fast. More fuel efficient is the saw tooth flight path. Starting with the engine until reaching the desired height, then gliding back.

By retrimming for higher speeds I noticed that a lot of re trimming is required. Connecting the trim with the flap position is advisable mainly because the desired trim position cannot be obtained by pulling the release handle on the control stick. The pilot must still adjust the trim knob on the left hand side.

In slow flight with a running engine, +10 degree flaps and 75 Km/h airspeed indicator the DG becomes soft. It shakes a little and by 70 Km/h it starts into a staggering sink flight. Pulling the control stick further back results in the glider turning over the right wing. The resulting turning spin can be corrected immediately and without difficulty.

The engine is stopped in the simple DG fashion:

Turn off the ignition and wait for the propeller to stop rotating. When you now push the ignition button the propeller slowly rotates to the vertical position and is then stopped and automatically retracted into the fuselage. The DEI automatically turns off the intercom of the on board radio. In order to properly compensate the variometer, the pilot switches the air intake from the static holes on the fuselage to the compensation holes on the tail fin. This is done because the static holes in the fuselage are directly in the turbulent air path of the propeller.

Pull-over-behavior and speed control in glide flight with +10 degree flaps does not vary much in comparison to engine flight. With the flaps in the landing position you can fly approximately three Km/h slower. If you use full flaps you can fly up to five Km/h slower which stabilizes the sink flight.

The 45 degree circle change is for a 20 meter bird quickly obtained:

In the thermal flap position +10 degrees and 95 Km/h in 5,7 seconds. By 0 degrees and 100 Km/h it can be obtained in under five seconds. The rudder adjustment is good by 0 degrees. In the early positive positions a little more rudder is required.

One other point to make is: the heavy two-seater even with it’s large wing loading can easily and effectively be thermals thanks largely to the winglets. The rudder strength could be somewhat smaller especially in the slower flight conditions. During fast flight you climb up once more. The DG-505MB lies quietly in the air.

One other point to make is: the heavy two-seater even with it’s large wing loading can easily and effectively be thermals thanks largely to the winglets. The rudder strength could be somewhat smaller especially in the slower flight conditions. During fast flight you climb up once more. The DG-505MB lies quietly in the air.

The connection trim flaps needs some improvement:

The trim is set to 80 Km/h and flaps at +10 degrees or 90 Km/h with 0 degrees or 115 Km/h in the fast flight position and -10 degrees. The trim in the lower speeds is enough, however during my single seated flight with the center of gravity positioned towards the rear, I could only reach 200 Km/h by pushing the trim setting as far forward as possible. This will however be corrected in the series production.

For the landing approach, the flaps are set to the “L” position. Normal landing speeds range from 100 to 105 Km/h plus the reserve wind. Steep approaches are no problem with the Schempp-Hirth brake flaps on the top surface of the wings. A slip can easily and with good results flown during approach.

We land in a two point position with nose and tail wheel simultaneously The main landing gear cushions nicely during landing and is superior thanks to it’s disc brake.

Even with the flaps in the landing position the aileron gives good control even while rolling out. For now the DG-505MB is the only two seated retractable glider in the 20 meter class.

In other words, it has no market competitors.

The new engine concept is based on the positive experience they have had with the production of the DG-808B. It is an independent and easy to fly motorized two seater.

The performance results in the 20 meter two seated class are very competitive. They could still be further improved if wings of the newest generation were used!

The optional 22 meter outer wing can still be ordered. They offer more performance and less wing loading for flights with weaker weather conditions. If you do not wish to fly in the 20 meter class.

Over all the DG-505MB is an interesting alternative for the performance and traveling glider pilots who appreciate the freedom, teamwork in the cockpit.

It can also be used rather well for other purposes. For the use in a club as a training glider for pilots learning to fly motor gliders as well as helping in the training of gliding ground principles and distance flight training!!

Jochen Ewald